Home > Durability Insights – Carbonation of BCSA Concrete

Carbonation is an important durability parameter to be considered in the design of reinforced concrete. While carbonation is not, per se, detrimental to concrete, it may lead to the corrosion of steel reinforcement and subsequent failure of the member. Atmospheric CO2 dissolves in water to create carbonic acid, and slowly seeps through pores in the concrete surface. The acid neutralizes the passivating layer of alkaline cement hydrates that protect the steel from environmental deterioration, which leads to cracking and eventually failure [1].

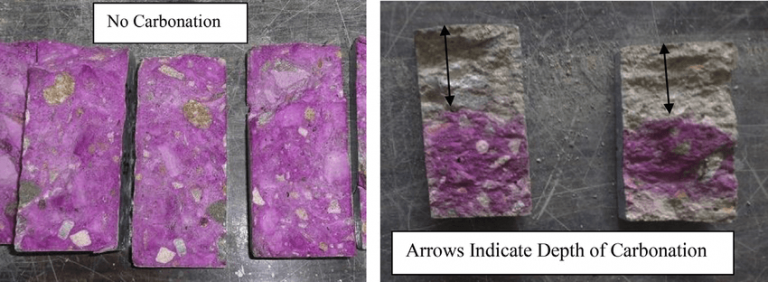

The rate of carbonation depends on several factors, such as cement type and quantity, water to cement ratio, effective curing, and quality of workmanship. This raises the question: Do BCSA cements exhibit similar carbonation resistance to Portland cements? A good question indeed, as the two cements have different primary hydration products. Fortunately, there is a relatively simple procedure for determining the degree of carbonation in a concrete section. The “Depth of Carbonation” test involves taking a core, splitting it in half, and then spraying the newly exposed surfaces with a phenolphthalein pH indicator. All concrete unaffected by carbonation will turn bright purple.

As part of Antoun’s E6TM Methodology and commitment to quality and innovation, carbonation was tested on cores from Runway 16R of Sydney Airport installed in 2016. The test, completed in accordance with RILEM CPC 18[2], found that after 3 years of in-situ exposure, the depth of carbonation was 10 mm. Depth of carbonation is proportional to the square root of time, such that:

What this means is that the rate of carbonation becomes progressively slower with time, and theoretically, the depth of carbonation will be only 37 mm at 40 years, and 58 mm at 100 years. For perspective, road pavements with a 40-year design life typically have a minimum cover of 50 mm.

If you read An Introduction to Concrete Durability, then you will know about the impermeable matrix produced by BCSA cement. Like the use of Fly Ash or Slag, the improved cement matrix allows only a slow ingress of CO2 [3], and more than off-sets the slight reduction in pH of the pore water in terms of whole-of-life durability. However, an interesting differentiator is the rate of strength gain between BCSA and Portland-pozzolan blends: while strict curing for the first 3 days is essential for high-SCM concrete mixes to develop the hydration products necessary for carbonation resistance, the accelerated hydration curve of BCSA means that 7-day strength is achieved in around 3 hours. In fact, the literature supports the idea that concrete strength on initial exposure is able serve as the basis for predicting carbonation without the need to account for method and duration of curing [4].

References

[1] Neville, A.M. (2011). ‘Properties of Concrete 5th edition’, Essex: Pearson Education Limited

[2] RILEM TC 56-MHM (1988), ‘CPC-18 Measurement of hardened concrete carbonation depth’, Materials and Structures, vol. 21, no. 126, pp. 453 – 455, RILEM Publications SARL

[3] Allevi, S., Borgschulte, A., Hargis, C.W., Kaufmann, J., Lothenbach, B., Marchi, M.I., Steiner, S. & Winnefeld, F. 2018, ‘Further Insights In The Carbonation Resistance of Calcium Sulfoaluminate Mortars’, International Workshop on Calcium Sulfoaluminate Cements, Murten, Switzerland

[4] Ekolu, S. 2016, ‘A review on effects of curing, sheltering, and CO2 concentration upon natural carbonation of concrete’, Construction and Building Materials, vol 127, pp.306-320.

Call

Call